Maintenance models based on IoT and Web App

Responsive maintenance

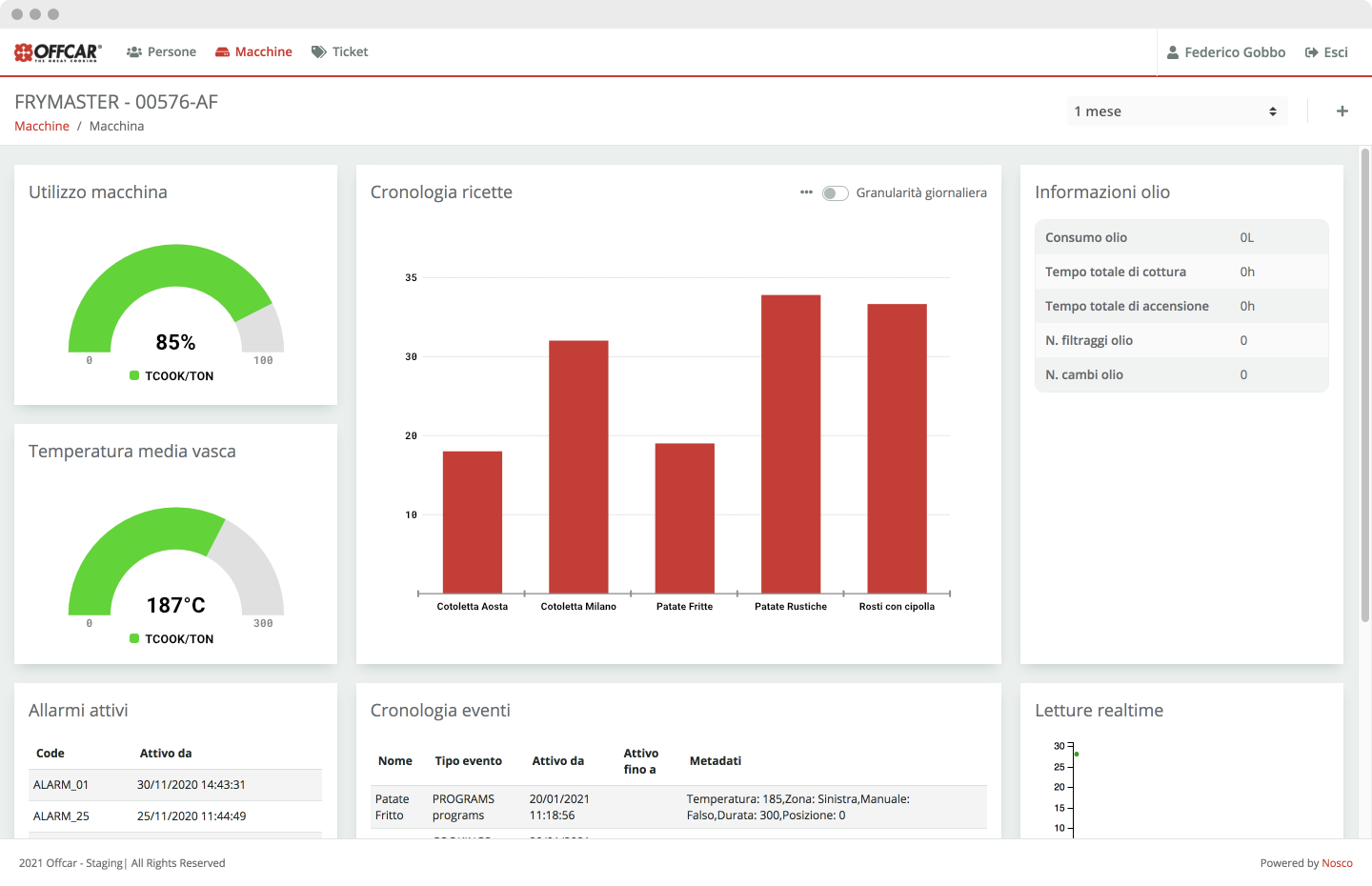

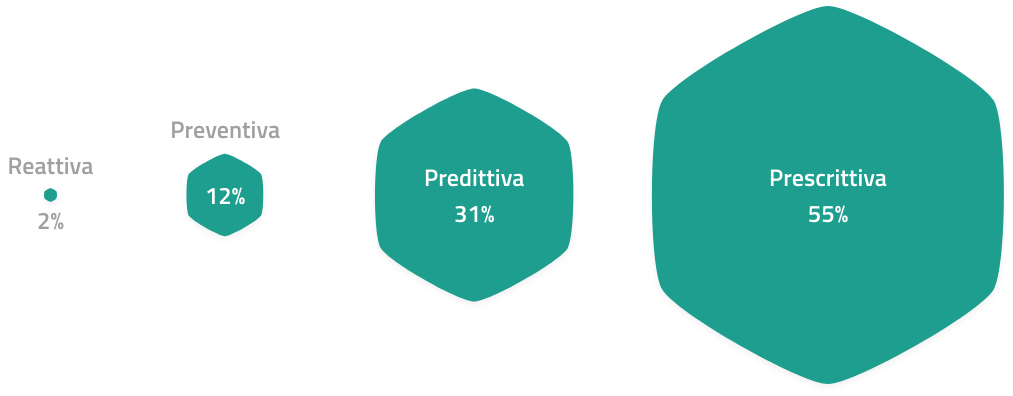

Reactive intervention is the most commonly used maintenance model: it consists in the repair of a machine following a failure that has already occurred. However, if you do not have process optimization tools, the intervention closing time expands, resulting in an increase in costs.

With Nosco IoT

The IoT platform allows you to have every phase of maintenance under control, from reporting the problem to its resolution. The operators in charge have the necessary information immediately available: customer records, product data sheets, the availability and competence of the network of technicians. Times are reduced and waste is reduced.

Preventive maintenance

Setting up preventive maintenance means scheduling periodic checks and efficiency of your product. The goal of this maintenance model is to prevent the occurrence of failures, even at the cost of resorting to a high number of unnecessary operations.

With Nosco IoT

Thanks to the IoT platform and the Web Application it is possible to manage everything remotely, scheduling and organizing interventions without having to waste energy in interacting with your technical park.

Predictive maintenance

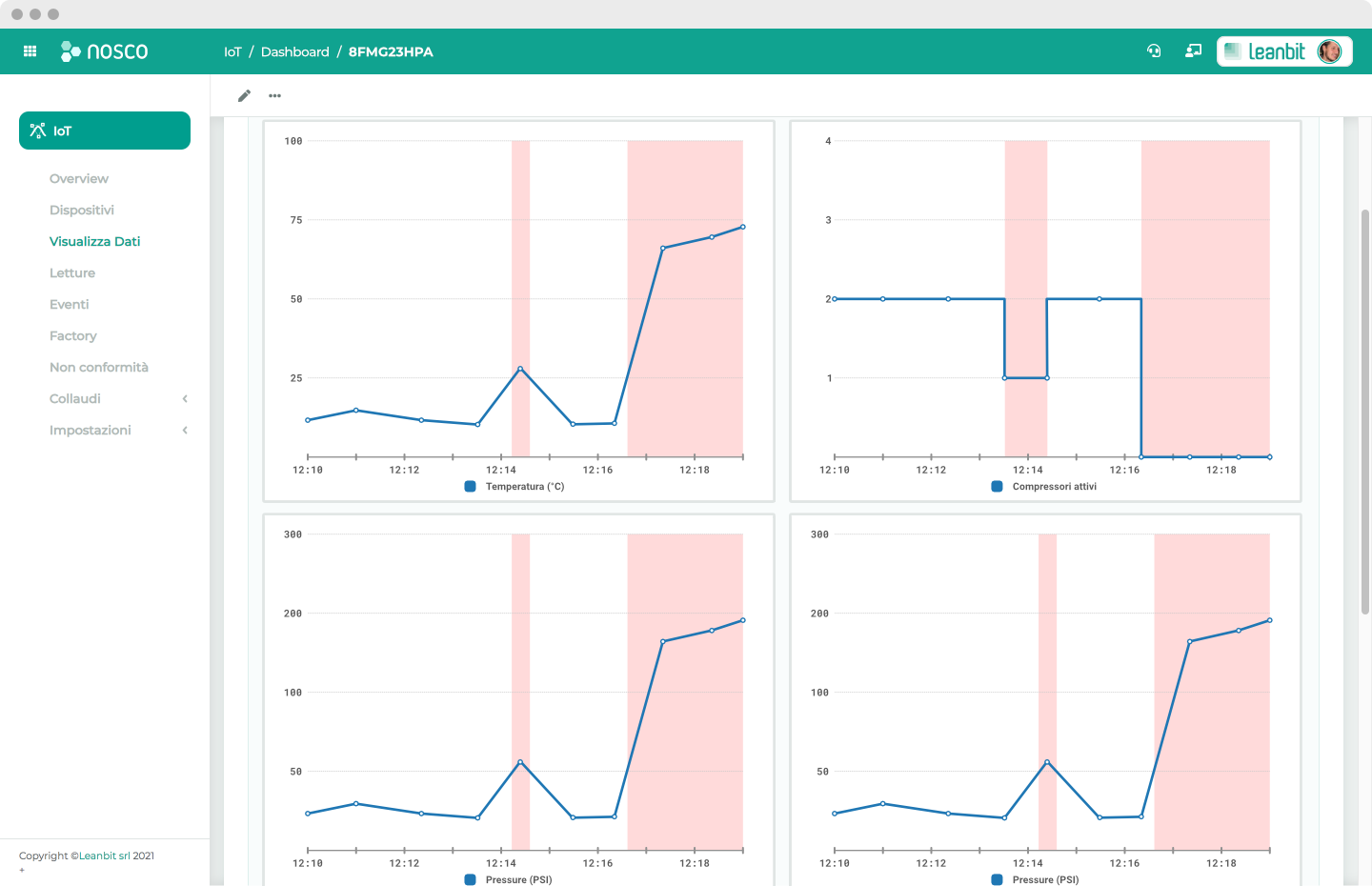

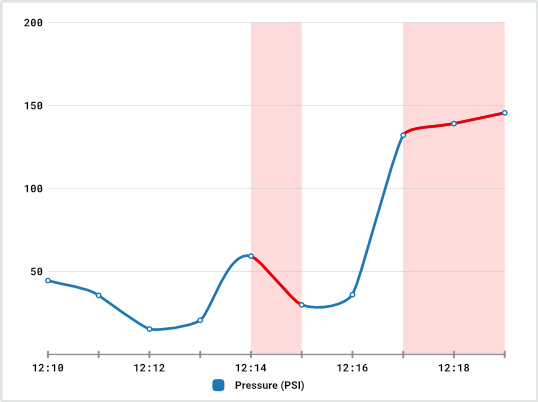

The predictive maintenance model is based on the remote monitoring of the machines connected to the platform, in order to plan an intervention before the occurrence of a real failure. Thanks to a data processing algorithm, it is possible to predict any problems, allowing a drastic reduction in failures and a series of targeted and fast interventions.

With Nosco IoT

The IoT module organizes and processes the data collected periodically from your machines connected to the internet. The accuracy of the information allows you to refine your prediction.

Prescriptive maintenance

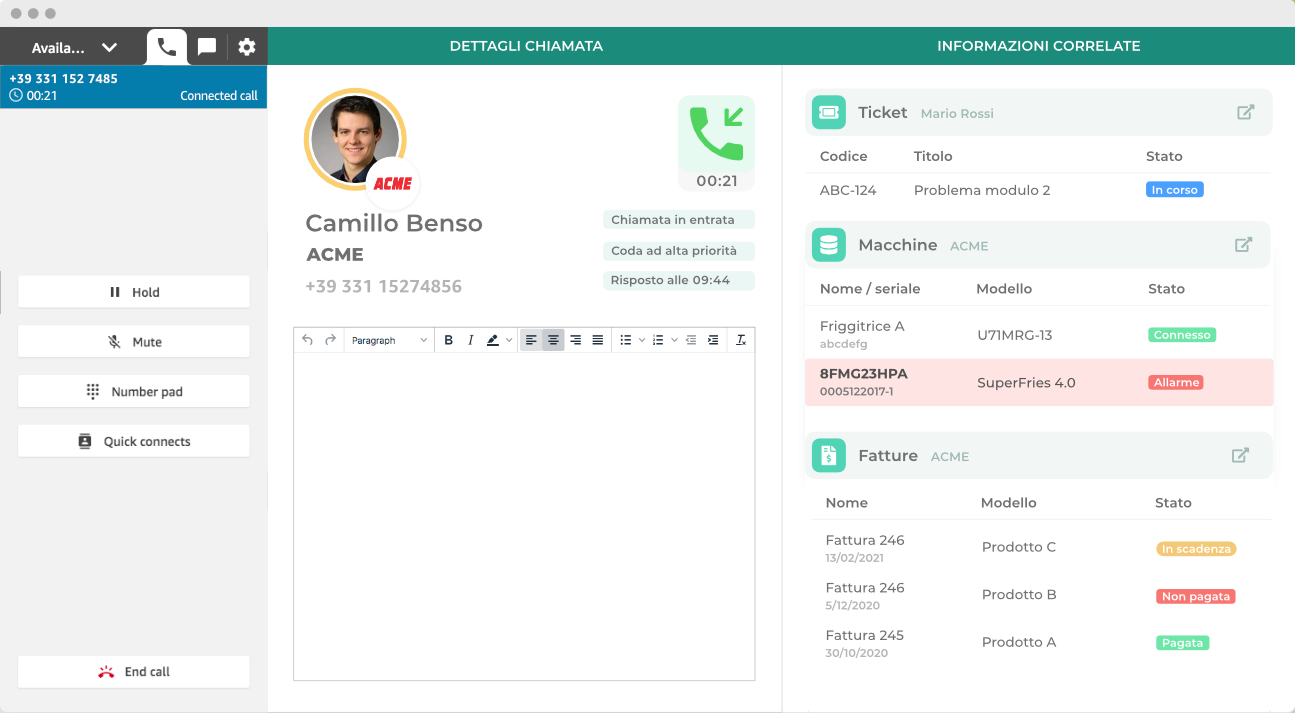

This model is an evolution of the predictive model and is able to make the most of the potential of the IoT platform. The data collected in real time on each individual product is combined with installation and testing information, the history of faults and the conditions that facilitate them. Performance is optimized and downtime is further reduced, thanks to continuous product adjustments.

With Nosco IoT

Thanks to Nosco it is possible to generate an information ecosystem of high value and in real time, which combines the information gathered from connected products and from interactions with customers. The reliability achieved makes it possible to promptly recommend intervention actions and monitor their impact.

Give your customers the information they need

A feature dedicated to your customers, agents and resellers

The Nosco IoT Customer Portal is a feature designed to allow your customers, agents and resellers to receive updated information about the machines they are using, in an easy and intuitive way. Through a remotely accessible interface, each customer will be able to monitor the status of the machines in real time and constantly keep the pulse of the situation.